Physical contact fiber optic connectors use precision alignment sleeves to align the mating fiber optic termini. These sleeves can be ceramic (zirconia) or metal (phosphor bronze). In recent years, the industry has favored ceramic because of superior manufacturing tolerances and repeatability. The tighter tolerances allow for better optical alignment and lower insertion losses.

Ceramic alignment sleeves are available in solid and split designs. Solid sleeves, continuous cylinders of ceramic, are favored in applications that require a high number (> 500) of mating cycles, due to their durability. The drawback to solid sleeves is that they cannot be reliably used for Singlemode fiber due to the need for clearance between the sleeve and the termini ferrule. This clearance, while necessary, translates to unacceptable and unpredictable optical losses in small core fibers.

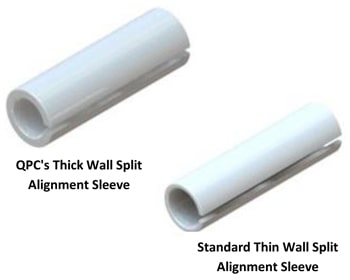

Split sleeves, with a slot running the length of the part, are designed to be slightly undersized to allow the termini to make contact with the walls of the sleeve. This results in the best possible optical alignment and minimizes losses for all fiber types. The drawback to split sleeves is their lack of durability. Ceramic is an inherently brittle material and standard thin wall ceramic split alignment sleeves have a wall thickness of just 0.014” (0.35mm) thick – approximately equivalent to the thickness of 4 sheets of standard copier paper. One of the most common failure modes for optical connectors is broken alignment sleeves, which results in a complete loss of the optical signal.

QPC Fiber Optic’s 2.5mm Thick Wall Split Sleeve Termini Alignment System improves reliability and extends product life for multichannel fiber optic connectors by combining the strength of a solid sleeve with the optical performance of a split sleeve. These sleeves are almost 80% thicker than a standard, thin wall, split alignment sleeve and have been successfully tested through thousands of mating cycles. QPC designed these sleeves into the QFoca Plug (M83526/16 Equivalent), QFoca Jam Nut Receptacle (M83526/17 Equivalent), QFoca Flange Mount Receptacle (M83526/18 Equivalent), and E-LINK (2-18 Pin/Socket + Hermaphroditic Channel Industrial Fiber Optic Connector System) connector families.

Sleeve Specifications (Thick Wall vs. Standard Thin Wall Split Sleeves)

| Type | Length (mm) | O.D (mm) | I.D. (mm) | Wall (mm) |

|---|---|---|---|---|

| Thick Wall Split Sleeve | 11.50 | 3.75 | 2.50 | 0.63 |

| Standard Wall Split Sleeve | 11.50 | 3.20 | 2.50 | 0.35 |

Durability Test

QPC’s QFOCA Connector (M83526/16 Equivalent) shown in Figure 1 below, which uses QPC’s Thick Wall Split Alignment Sleeves, and a competitor’s M83526/16 compatible connector shown in Figure 2 below, which uses standard thin wall split sleeves, were subjected to 500 mating cycles in a controlled laboratory environment.

The QPC QFOCA Connector passed the test and exhibited the same optical loss (± 0.10 dB) throughout the test. The competitor’s connector failed the test due to one of the two alignment sleeves breaking after approximately 300 cycles and resulting in the loss of one of the optical channels (Channel S1 – lower left in Figure 2 below).